Thermal Imagery Services

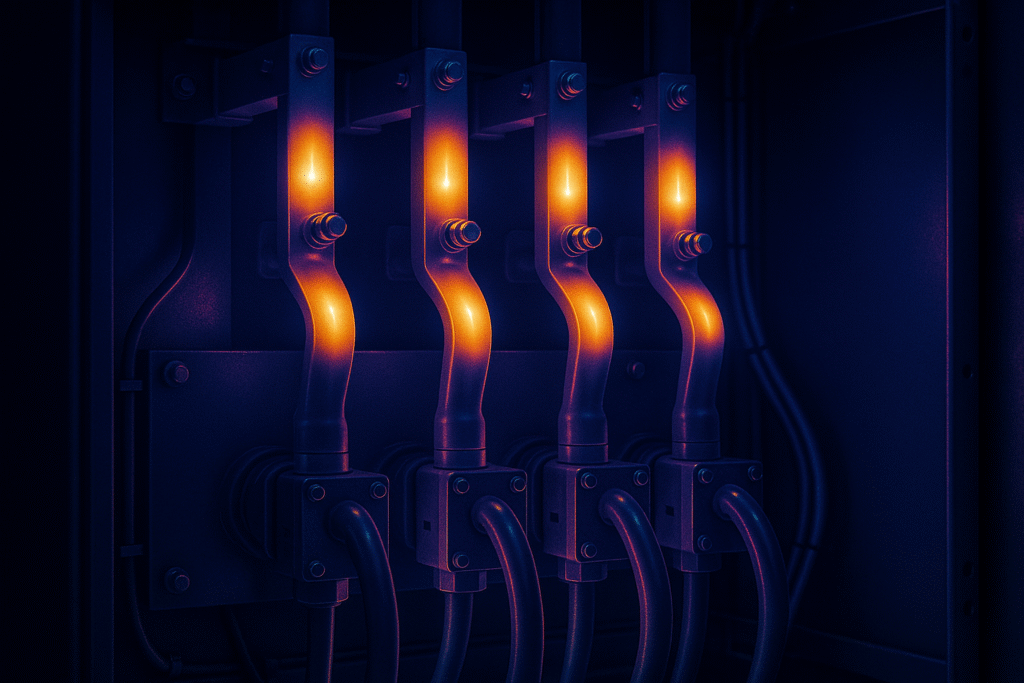

Our infrared thermography inspections in Dubai detect load imbalances and faults in switchgear. DEWA-compliant thermal surveys prevent arc flash risks. Schedule a thermal imaging inspection for tailored solutions!

Predictive Maintenance Solutions

Watts & Ergon’s thermal imaging for industrial facilities in UAE uses IR cameras to extend equipment life. Our experts deliver predictive maintenance strategies. Request a thermal survey for customized results!

Infrared Thermography Inspections

Our infrared thermography inspections in Dubai detect load imbalances and faults in switchgear. DEWA-compliant thermal surveys prevent arc flash risks. Schedule a thermal imaging inspection for tailored solutions!

Let’s Get Started

Our Three Step Procedure

1. Consultation

Our team will conduct a thorough assessment of your energy needs.

2. Installation

Our team will conduct a thorough assessment of your energy needs.

3. Monitoring

Our team will conduct a thorough assessment of your energy needs.

OUR SERVICES

Explore Our Services

Grow with Thermal Imagery: Secure Dubai Facilities

Watts & Ergon’s Thermal Imagery Services enhance electrical safety and operational efficiency for Dubai’s commercial and industrial sectors through advanced infrared thermography inspections. As a DEW... Read More

FAQs

Thermal imaging uses infrared cameras to detect heat patterns in electrical panels, helping identify potential faults, overloads, or hotspots before they cause failures.

Infrared thermography detects abnormal heat in electrical systems by capturing thermal images, allowing engineers to pinpoint issues without shutting down equipment.

Thermal scanning helps prevent costly downtime, reduces the risk of electrical fires, and ensures optimal performance of switchgear, distribution boards, and industrial electrical systems.

Yes, thermal imaging can reveal hotspots, loose connections, and load imbalances in switchgear, enabling proactive maintenance and enhancing operational safety.

IR inspections of distribution boards (DB panels) identify overheating circuits, faulty breakers, and potential arc flash risks without interrupting operations.

By detecting electrical faults early, predictive maintenance reduces unplanned downtime, extends equipment life, and improves energy efficiency across facilities.

Let’s Get Started

Contact Us

Straight from our desk, to your Inbox.

Submit Your Request for Your Enquiry

We working with customers brands and startups